The Complete Cummins Fault Code List

Cummins engines are renowned for their reliability and durability, but even the best engine can develop faults. Cummins fault codes indicate a malfunction has occurred in one or more of the vehicle’s components. Knowing Cummins fault codes is essential to diagnosing and fixing any problems with your Cummins engine quickly and efficiently. This article will provide an overview of Cummins fault code list reports and offer troubleshooting tips on how to interpret them so you can quickly and easily identify the root cause of any issue quickly and easily.

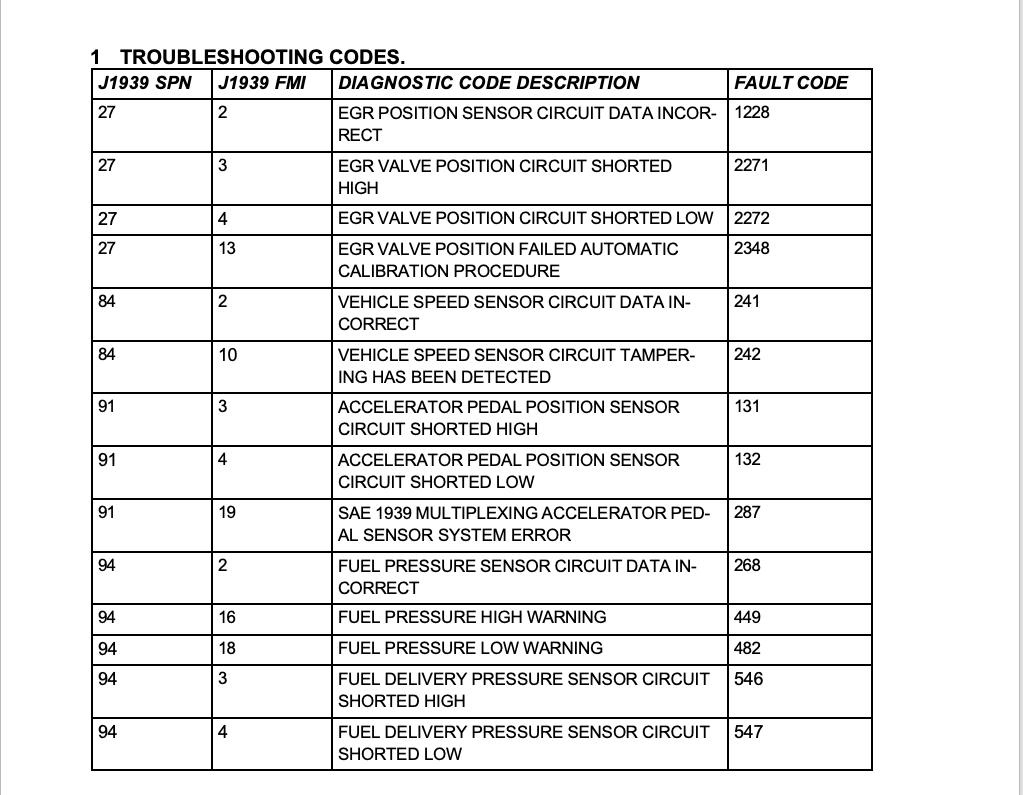

The first column of the following chart indicates the Suspect Parameter Number (SPN). The second column shows Fault Mode Identifier (FMI) numbers. Followed by a description and then the code itself.

Check out these videos for additional Cummins training

Best practices for maintaining your cummings engine in top condition

To begin with, it's important to become familiar with cummings fault codes, their meanings, and how to interpret Cummins fault code list reports. As mentioned earlier, cummings fault codes indicate a malfunction has occurred in one or more of the engine's components. Knowing Cummins fault codes is essential for diagnosing and fixing any problems quickly and efficiently.

Regularly checking your cummings engine for signs of wear and tear is also important. Make sure to check fuel injectors, hoses, spark plugs, air filters, oil levels, coolant levels, and other components for any abnormalities. Additionally, it’s essential to keep track of the Cummins engine’s service history and to follow the suggested maintenance schedule outlined by cummings. Doing so will help you catch and prevent potential problems before they become serious.

In conclusion, Cummins fault codes are essential for diagnosing and fixing any problems quickly and efficiently. It’s important to become familiar with cummings fault codes, their meanings, and how to interpret Cummins fault code list reports in order to identify the root cause of any issue. Additionally, it is important to keep track of your Cummins engine's service history and follow a suggested maintenance schedule outlined by cummings in order to catch potential problems before they become serious issues. By following these best practices for maintaining your cummings engine in top condition, you can ensure that your vehicle runs smoothly at all times!